The emergence of rapid tooling techniques remains a transformative force in the ever-growing expansion of modern manufacturing essentially reshaping the face of prototype injection molding. Pioneers of this approach have emerged as a key factor in bringing high-quality prototypes to projects. A seamless blend of speed accuracy and cost rapid tooling is emerging as a cornerstone heralding a new era in rapid prototyping

Specifically, the rapid integration of tools in prototype injection molding marks a departure from traditional norms creating a field where innovation and performance merge. This new approach is not like it not only accelerates the development cycle but sets new standards for accuracy and cost-effectiveness. It is an indispensable asset in the arsenal of businesses committed to pushing the boundaries of efficiency

Understanding Rapid Tooling in Prototype Injection Molding

Rapid tooling is basically about quickening the production of molds for prototype injection molding, utilizing high-tech materials and mechanisms. This process facilitates the rapid creation of molds that are vital for the injection molding process, allowing manufacturers to bring their designs from concept to reality instantly compared to traditional methods.

What is Rapid Tooling?

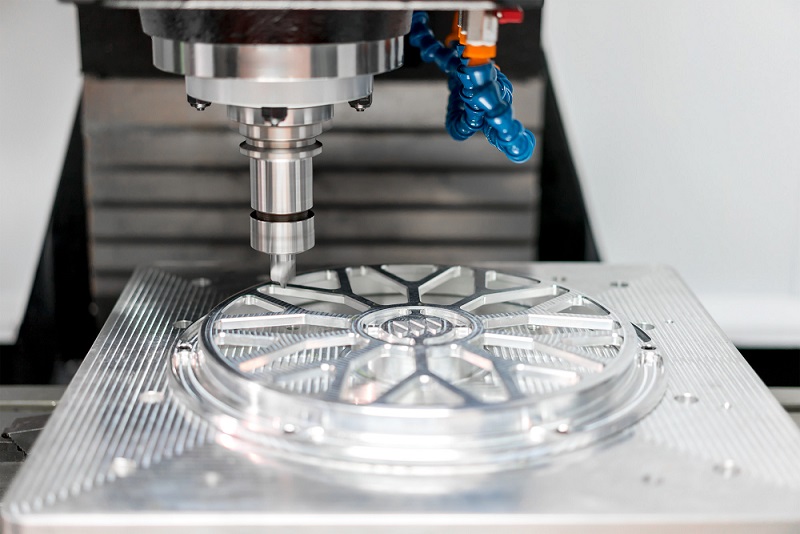

Think of it as a gap between standard prototyping and full-scale production. Rapid tooling utilizes advanced technologies such as CNC machining 3D printing and injection molding to create useful prototypes. This allows manufacturers to test their designs, gather feedback and refine the product before committing to mass production.

Key Components of Rapid Tooling for Prototype Injection Molding

The efficacy of rapid tooling lies in its intricate yet well-coordinated key components. These pivotal elements collectively contribute to the accelerated and precise creation of molds setting the stage for the seamless development of prototypes. Let’s delve into the essential components that constitute the backbone of rapid tooling.

Master Patterns

At the core of rapid tooling is the creation of incredible patterns. These drawings are digital prototypes carefully created using state-of-the-art computer-aided design (CAD) software. The transition from the virtual realm to a physically tangible environment is made possible by modern technologies such as 3D printing, CNC machines other manufacturing processes etc. This basic example closes the foundation for the next phase of rapid tooling for prototyping

Tooling Inserts

Attained from the master patterns, tooling inserts play a vital role in shaping the final product during injection molding. Composed from durable materials such as aluminum or steel these inserts embody longevity and precision. Their robust construction ensures incessant use contributing to the efficiency of the rapid tooling process. The choice of materials for tooling inserts is a judgmental decision that affects the quality and lifespan of the molds.

Rapid Prototyping Technologies

Blending unconventional technologies such as Direct Metal Laser Sintering (DMLS) amplifies the rapid tooling process. DMLS, for instance, involves layer-by-layer fusion of metal powders using a laser resulting in highly accurate and tangled tooling inserts. This technology not only fastens the manufacturing process but also adds to the precision and convolution achievable in rapid tooling.

Soft Tooling

Soft tooling presents adjustability in the rapid tooling landscape. Making use of softer materials like silicone or aluminum soft tooling proves to be a cost-effective solution especially suitable for low-volume production runs. While not as hard-wearing as traditional steel tooling soft tooling is ideal for quick iterations in the prototyping phase offering briskness in adapting to design changes.

Mold Bases and Components

To smoothen the mold-making process standardized mold bases and components play a determining role. These quickly available off-the-shelf elements expedite the overall tooling production. Utilizing stock mold components and bases hastens up the timeline for creating molds allowing for faster repetitions and production.

CNC Machining and Additive Manufacturing

The bond of CNC machining and additive manufacturing techniques contributes to the accuracy and speed of rapid tooling. CNC machining allows for the precise shaping of molds while additive manufacturing methods such as 3D printing offer adaptability in creating complex geometries. The union between these manufacturing techniques ensures a holistic approach to rapid tooling, combining accuracy and efficiency.

Methods Engaged in Rapid Tooling for Prototype Injection Molding

The smooth confluence of advanced techniques is the authentication of rapid tooling for prototype injection molding allowing for quick and accurate production of molds. These methods each playing a distinctive role jointly contribute to the productivity and success of the rapid tooling process. Explore the key techniques that state the era of rapid tooling in prototype injection molding.

Direct Metal Laser Sintering (DMLS)

DMLS is a 3D printing method, utilizing a computer-controlled, high-energy laser beam to melt and unite film/layers of metallic powder. Direct metal laser sintering (DMLS) is an industrial 3D printing procedure that can establish fully operational metal prototypes and production elements within an exceptional timeframe of 7 days or fewer.

DMLS not only quickens the production of molds but also enhances the overall accuracy, allowing for the production of complex shapes that conventional methods may scuffle to attain.

Soft Tooling for Rapid Injection Molding

Soft tooling established an element of flexibility in the rapid tooling range. By utilizing softer materials like silicone or aluminum this method offers a practically profitable solution specifically suitable for prototypes or low-volume production runs. The variety of soft tooling allows for speedy repetitions during the prototyping phase, smoothening the methodical adjustments to design changes.

Machined Aluminum or Soft Steel Mold Cavities

Fast mold-making is achieved through the utilization of machined aluminum or soft steel mold cavities. This technique emphasizes simplicity in mold design leveraging stock mold components and mold bases to expedite the tooling process. The choice of materials ensures durability while contributing to the acceleration of low-volume moldings.

Rapid Injection Molding

Beyond regular production molding, rapid injection molding is a technique that emphasizes speed and efficiency. With a dedicated setup of over 10 injection molding machines 3ERP is equipped to handle prototype or small-quantity molding projects. The molds seamlessly transition from production to machines without delays, contributing to a streamlined and agile manufacturing process.

Stock Mold Components and Mold Bases

Systemized mold substructures and components play a crucial role in the rapid tooling process. These sometimes neglected elements provide efficient mold-making reducing lead times. By having readily available components manufacturers can fasten the production of molds allowing for rapid recurrence and adjustments during the prototyping phase.

Simplified Mold Design

Bringing attention to simplicity in mold design is a key technique in rapid tooling. By utilizing stock mold components and mold bases the overall scaling process is organized speeding up the tooling production. This approach not only steps up the manufacturing ordering but also enhances the efficiency of the entire injection molding process.

Advantages of Rapid Tooling in Prototype Injection Molding

Rapid tooling in prototype injection molding offers a plethora of advantages, revolutionizing the traditional approach to mold creation and prototype development. These dominating points add to escalated speed cost-effectiveness, and overall variability in the manufacturing process of prototype injection molding.

Accelerated Time-to-Market

One of the predominant advantages of rapid tooling is the astonishing depletion in the time required to bring a product to market. By fastening the mold production process manufacturers can quickly move from design conception to physical prototypes and later on to the production phase. This acceleration is especially important in industries distinguished by fast-paced novelty, providing a competitive edge.

Cost Efficiency

Rapid tooling is a cost-effective substitute compared to conventional tooling methods. By leveraging modern technologies and optimized processes, manufacturers can notably lessen the production costs linked with mold production. This cost efficiency is particularly preferable for businesses seeking to smoothen their prototyping processes without striking the balance on the quality of the end product.

Repetitive Prototyping

Rapid tooling clears the way for repetitive prototyping with ease. Manufacturers can speedily modify and process designs based on initial prototypes allowing prompt adjustments in response to feedback or design improvements. This iterative step is indispensable in the early stages of product development allowing for efficient testing and authentications of design concepts.

Flexibility in Design Changes

The flexibility offered by rapid tooling extends to accommodating design changes. Far from conventional tooling methods that may be inflexible and time-consuming to change rapid tooling allows for quick adjustments. This adaptability proves vital in dynamic industries where design alterations are a common and necessary part of the product development process.

Precision and Quality

Despite the fast-paced nature of the process, rapid tooling does not bargain on precision and quality. The modern technologies employed in rapid tooling such as CNC machining and additive manufacturing make sure that the resulting molds and prototypes maintain a high level of exactness. This precision is pivotal in producing prototypes that closely resemble bulk production components.

Streamlined Production Scaling

For industries that emphasize on transition from prototyping to mass production, rapid tooling provides a coherent shift. The technologies and processes associated with rapid tooling allow for efficient scaling of production making sure a smooth continuation from small-batch prototyping to larger production.

Closing Statement

In conclusion the blend of rapid tooling in prototype injection molding emerges as a transformative force in modern-era manufacturing. By utilizing advanced materials and the latest cutting-edge techniques manufacturers can attain exceptional speed, precision and cost efficiency in bringing their designs to life. As industries continue to advance adopting the power of rapid tooling becomes strategically all-important for staying ahead in the competitive landscape.